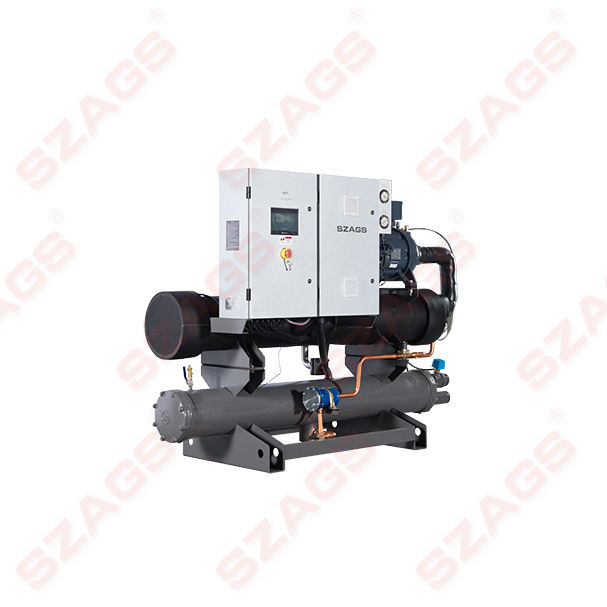

Ağır Endüstriyel İhtiyaçlar İçin 150 HP Yüksek Kapasiteli Soğutma Su Soğutucu Birim

Ürün Genel Görünümü

Büyük ölçekli endüstriyel üretim için bir çekirdek soğutma ekipmanı olarak, 150HP su soğutmalı vida soğutucusu, 539Kw (463,884Kcal/h) 'a kadar bir dondurma kapasitesine sahiptir.Kimyasal reaktörler gibi yüksek ısı yükü senaryolarını verimli bir şekilde işleyebilen, büyük ölçekli plastik enjeksiyon kalıplama atölyeleri ve metalürji işleme hatları.güçlü yük taşıma kapasitesine sahip çift vidalı bir kompresör tasarımı benimser, % 80-100 yük koşullarında 24 saat boyunca sürekli çalışabilir ve istikrarlı çalışma oranı% 99.5'ten fazlaSoğutma ekipmanı arızalarından kaynaklanan üretim kesintilerinin etkili bir şekilde önlenmesi.

Petrokimya endüstrisinde, örneğin, reaksiyon sisteminin ısı değişim ortamını soğutabilir, reaksiyon sıcaklığını ± 1 ° C içinde kontrol edebilir, kimyasal reaksiyonların istikrarını sağlayabilir,ve yan ürünlerin üretimini azaltmak• Otomobil parçaları imalat endüstrisinde, büyük damgalama ölçekleri için eşit soğutma sağlayabilir, kalıp soğutma süresini % 30 oranında kısaltabilir,ve otomobil parçalarının üretim ritmini önemli ölçüde iyileştirmek.

Temel bileşen: Verimlilik ve istikrar için vida kompresörü

Soğutucu, uluslararası tanınmış markalardan yüksek verimli çift vidalı bir kompresörle donatılmıştır ve bu, geleneksel ters kompresörlere kıyasla açık avantajlara sahiptir:

- Enerji tasarrufu: Dahili asimetrik rotor tasarımı, kompresörün iç sızıntılarını azaltır ve hacmi verimlilik% 95'ten fazla olur.Enerji tüketimi, ters kompresörlere göre %15-20 daha düşüktür., ve işletmeler için yıllık enerji tasarrufu on binlerce yuan'a ulaşabilir.

- Düşük titreşim ve gürültü: vida dönüş hızı sabit (3000-4500r / min) ve titreşim amplitudu 3mm / s'den azdır. Eşleşen şok emici tabanla,Çalışma gürültüsü 75dB ((A) altında kontrol edilir., geleneksel modellerin 85dB ((A) 'dan çok daha düşüktür ve daha sessiz bir atölyesi ortamı yaratır.

- Uzun Hizmet Ömrü: Rotor, aşınmaya dayanıklı ve korozyona dayanıklı olan HRC58-62 yüzey sertliği ile hassas dövme yoluyla yüksek dayanıklılıklı alaşımlı çelikten yapılmıştır.Kompresörün tasarım ömrü 15 yıldan fazla, ve ortalama bakım döngüsü 2-3 yıla uzatılır.Teknik özellikler

Soğutma Sistemi: Sıcaklığı verimli bir şekilde dağıtmak için su soğutma tasarımı

Soğutucu, büyük bir ısı değişimi alanına sahip (en fazla 180m2) bir kabuk ve boru kondansatörü kullanır.Endüstriyel dolaşım suyuna karşı güçlü korozyon direnci (korrozyon inhibitörleri gibi)Su akışı kanalı, sıvı dinamik simülasyonu ile optimize edilir ve bu da su direncini sıradan kabuklu ve boru kondansörlerine kıyasla %12 azaltır.ve ısı değişimi verimliliği %18 artar..

Çeşitli soğutma su kuleleri ile eşleşmeyi destekler (karşı akış, çapraz akış) ve su kaynağı sıcaklığı 30-40°C arasında ayarlanabilir.Yüksek sıcaklıklı mevsimlerde bile (çevre sıcaklığı 42°C'ye kadar), su akışı kontrol valfinin otomatik ayarlanması sayesinde sabit soğutma performansını koruyabilir.soğutma suyundaki kirlilikleri etkili bir şekilde filtreleyebilen, kondansör borusunun tıkanmasını önlemek ve manuel temizleme sıklığını %60 azaltmak.

Kontrol Sistemi: Tam Yönetim için Akıllı PLC

Soğutucu, aşağıdaki işlevleri gerçekleştirebilen endüstriyel bir PLC kontrol sistemi (Modbus, Profinet protokolleriyle uyumlu) ile donatılmıştır:

Kesin sıcaklık kontrolü: Çıkış suyunun sıcaklığı 5-20°C aralığında ayarlanabilir ve kontrol hassasiyeti ±1°C'ye ulaşır.Gerçek soğutma talebine göre kompresör yükünün otomatik ayarlanmasını destekler (yük ayar aralığı 25%-100%), düşük talep altında yüksek yüklü işletimden kaynaklanan enerji israfını önlemek.

Uzaktan İzleme ve Kontrol: Fabrikanın MES sistemi ile bağlantı yoluyla yöneticiler çalışma parametrelerini (soğutma kapasitesi, su sıcaklığı,basınç) ve bilgisayar veya mobil terminalde gerçek zamanlı olarak soğutucunun arıza bilgileri, ve ekipmanın başlangıç, durma ve parametreler ayarını uzaktan kontrol ederek insansız yerleşik yönetimi gerçekleştirir.

Hata erken uyarı ve teşhisi: Sistem gerçek zamanlı olarak 32 önemli parametreyi (kompresör boşaltma sıcaklığı, kondansör basıncı, su akışı hızı vb.) izleyebilir.Anormal bir parametreler tespit edildiğinde, hemen ses ve ışık alarmı ve uzaktan mesaj hatırlatması gönderecek ve hata yerini ve bakım önerilerini kontrol paneline gösterecek,bakım süresini %50'den fazla azaltır.

Teknik parametreler tablosu

|

Ürün

|

Parametreler

|

|

Soğutma kapasitesi

|

150 HP (539.4 kW)

|

|

Girdi Gücü

|

112.2kW (tam yük)

|

|

Soğutma yöntemi

|

Su soğutmalı

|

|

Sıcaklık aralığı

|

-5°C~35°C (özelleştirilebilir)

|

|

Su Akış Hızı

|

69.3m3/h

|

|

Kompresör markası

|

Hanbell/Bitzer (ihtiyaç duyulmaz)

|

|

Gürültü seviyesi

|

≤75dB ((A)

|

|

Boyutlar (L × W × H)

|

3400×1100×2610 mm

|

|

Ağırlık

|

2860 kg

|

Tipik Uygulamalar

1Sanayi Üretimi

Plastik işleme, elektronik çip imalatı, kimyasal ilaçlar ve gıda dondurma gibi endüstrilerde yaygın olarak kullanılmaktadır.üretim ekipmanları için sabit düşük sıcaklıklı soğutma suyu sağlar, sorunsuz süreç akışını sağlamak ve ürün kalitesini ve üretim verimliliğini artırmak.

2.Ticari binalar

Büyük alışveriş merkezlerinde, ofis binalarında, otellerde vb. merkezi klima sistemleri için uygundur.İç mekanlar için rahat bir soğutma etkisi sağlar ve büyük ölçekli alanların sabit sıcaklık gereksinimlerini karşılar.

3Veri Merkezleri ve Laboratuvarları

Veri merkezlerindeki sunucu ısı dağılımı ve laboratuvarlardaki hassas enstrümanların sıcaklık kontrolü için hassas ve istikrarlı soğutma sağlar.ekipmanların normal çalışmasını ve deney verilerinin doğruluğunu sağlamak.

Kişiselleştirme Hizmetleri

▶İsteğe bağlı yükseltmeler:

- Patlama geçirmez tasarım (ATEX sertifikalı)

- Ultra düşük sıcaklık versiyonu (-30°C ~ 5°C)

- Paslanmaz çelik tank/pompa (korrozyona dayanıklı)

- Çoklu birim paralel sistemler (ölçeklenebilir)

▶ Satış sonrası destek:

- Tüm ünite için 1 yıllık garanti, kompresör için 1 yıllık garanti

- 48 saat hızlı yanıt, ulusal servis ağı

- Ücretsiz operatör eğitimi + ömür boyu teknik destek

Başvuru Davası

Dava 1: Elektronik Çip Üretim Şirketi

- Gereklilik: Çip üretim hattındaki litografi makineleri ve kazma makineleri gibi hassas ekipmanlar için istikrarlı düşük sıcaklıklı soğutma sağlamak,Üretim ortamının sıcaklık dalgalanmasının ±0'u geçmemesini sağlamak.5°C.

- Çözüm: İki 240HP su soğutmalı vida soğutucu paralel olarak çalıştırılır ve gereksiz yedekleme ve hassas sıcaklık kontrolü elde etmek için akıllı bir kontrol sistemi ile birleştirilir.

- Etki: Ekipman istikrarlı bir şekilde çalışır, üretim verimi %98'in üzerinde artır ve yıllık elektrik maliyeti yaklaşık 300.000 yuan tasarruf edilir.

Durum 2: Büyük bir ticari kompleks

- Gereklilik: Enerji tüketimi maliyetlerini düşürerek yazın en yoğun saatlerinde yüksek yüklü soğutma talebini karşılamak için alışveriş merkezinin merkezi klima sistemine soğutma sağlamak.

- Çözüm: Gerçek zamanlı yüklemeye göre işletim birimlerinin sayısını otomatik olarak ayarlamak için bir grup kontrol sistemi ile birleştirilen üç 240HP su soğutmalı vida soğutucu takılır.

- Etki: Yaz iklimlendirme işletme maliyeti %25 azalır, iç mekan sıcaklığı eşit ve konforludur ve müşteri memnuniyeti önemli ölçüde artırılır.

Şimdi Bizimle İletişim Kurun

Profesyonel mühendislik danışmanlığı ve özel çözümler için +86 15875095305'i arayın!

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!